- +86-0533-2185556

- WhatsApp: +86 15965530500

- admin@hangyubiotech.com

Your Location:Home >Products >small-molecule inhibitor >1962-75-0

pd_meltingpoint:16℃

Purity:99%

|

General Description |

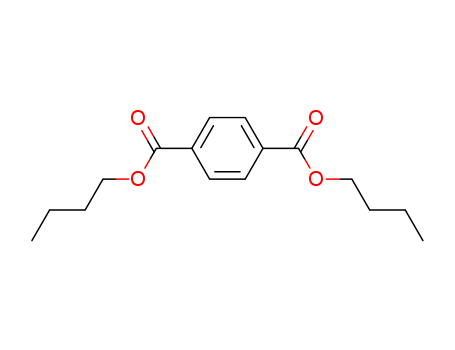

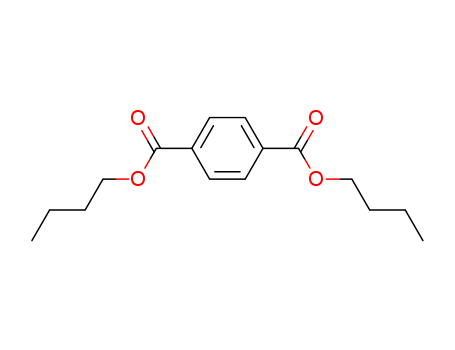

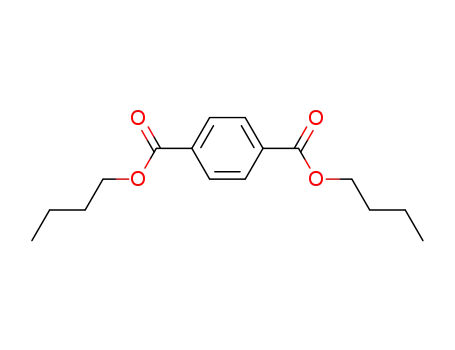

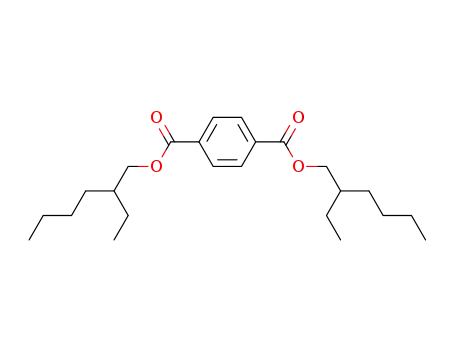

Dibutyl terephthalate is a chemical compound commonly used as a plasticizer and fragrance ingredient. It is derived from terephthalic acid and is used to enhance the flexibility and durability of various materials such as polymers, resins, and adhesives. Dibutyl terephthalate is also utilized in the production of personal care products, including cosmetics and perfumes, to impart a pleasant scent and improve the texture of the final product. However, |

InChI:InChI=1/C16H22O4/c1-3-5-11-19-15(17)13-7-9-14(10-8-13)16(18)20-12-6-4-2/h7-10H,3-6,11-12H2,1-2H3

Pd-catalyzed carbonylation, as an effici...

The palladium-catalyzed alkoxycarbonylat...

A plasticizer composition and a resin co...

Provided is a method for manufacturing a...

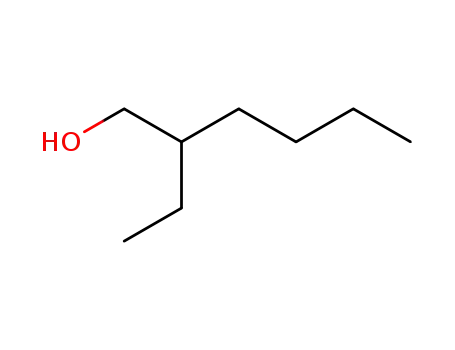

2-Ethylhexyl alcohol

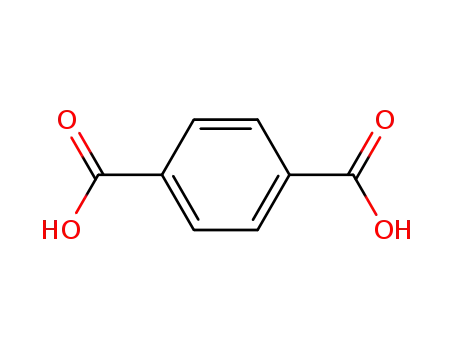

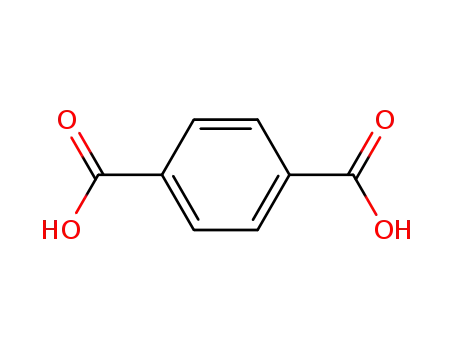

terephthalic acid

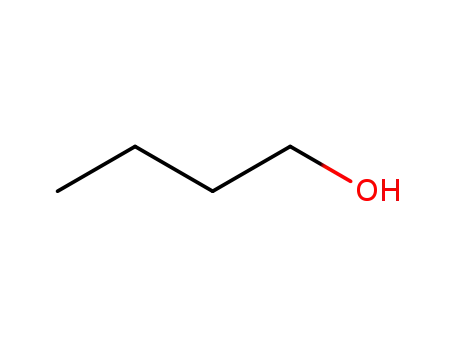

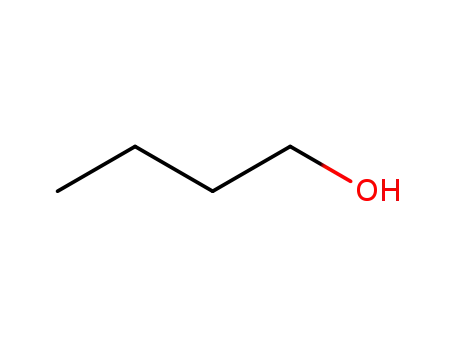

butan-1-ol

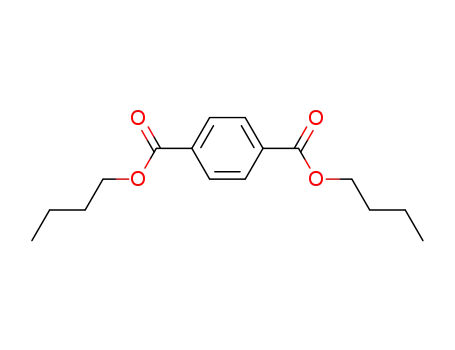

di-n-butyl terephthalate

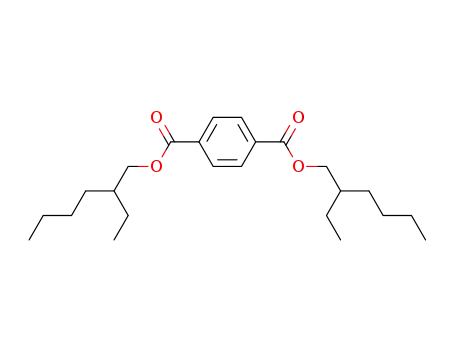

di(2-ethylhexyl)terephthalate

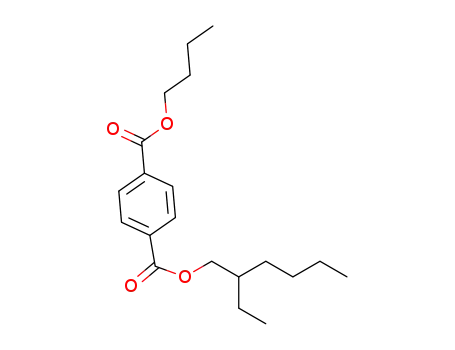

1-butyl 4-(2-ethylhexyl)terephthalate

| Conditions | Yield |

|---|---|

|

With

methanesulfonic acid;

at 210 ℃;

for 4h;

under 760.051 Torr;

Inert atmosphere;

|

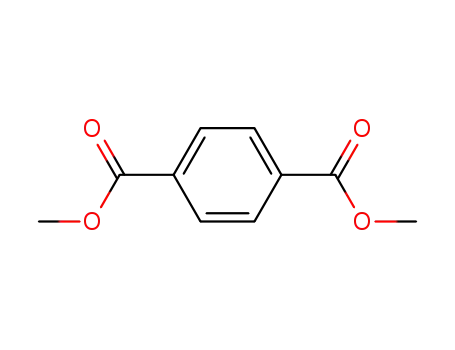

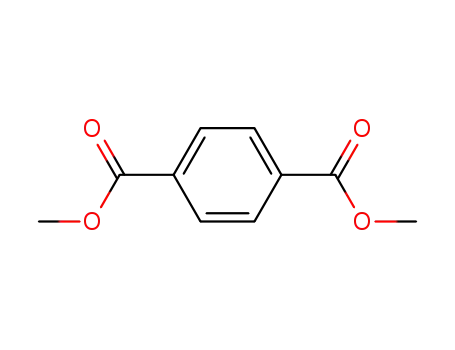

1,4-benzenedicarboxylic acid dimethyl ester

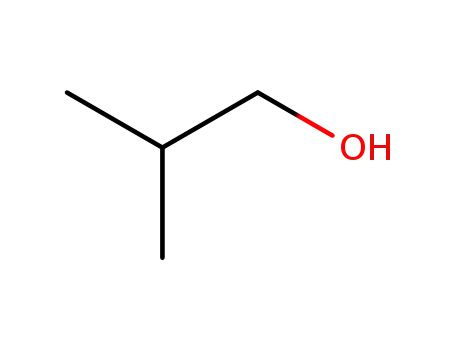

2-methyl-propan-1-ol

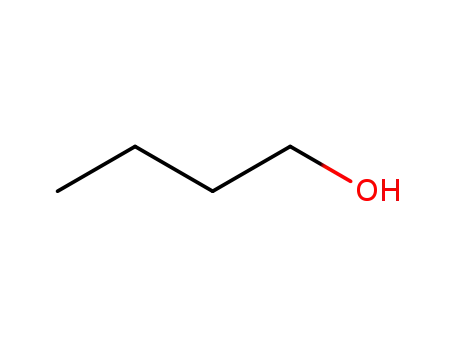

butan-1-ol

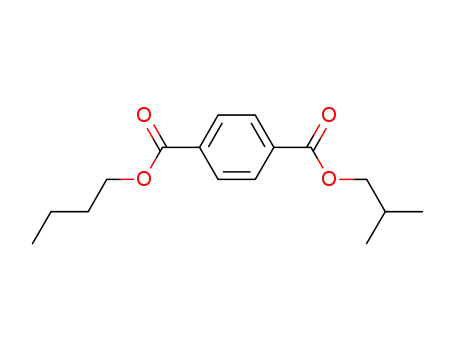

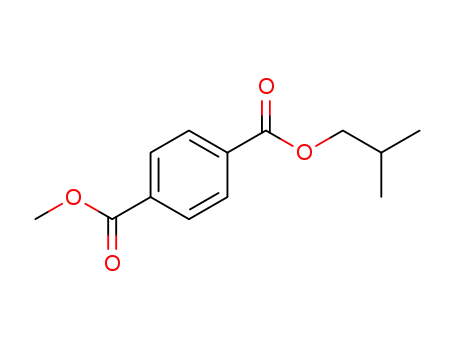

n-butyl isobutyl terephthalate

di-n-butyl terephthalate

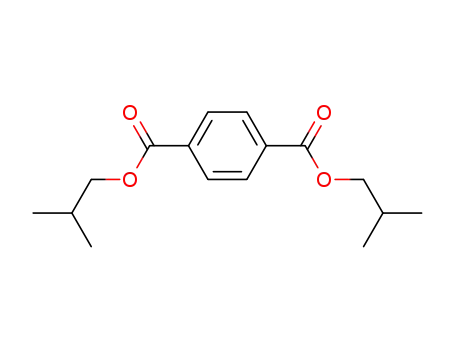

diisobutyl terephthalate

methyl isobutyl terephthalate

| Conditions | Yield |

|---|---|

|

With

Amberlyst 35 resin;

at 120 - 140 ℃;

Overall yield = 92.2 %; Overall yield = 76.987 g;

|

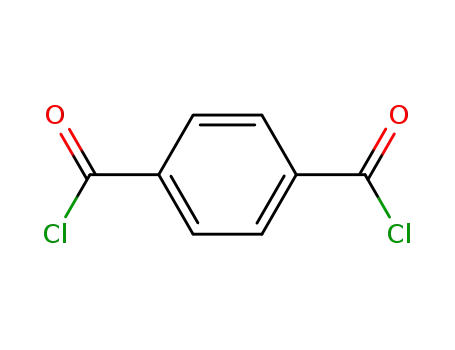

terephthaloyl chloride

butan-1-ol

1,4-benzenedicarboxylic acid dimethyl ester

terephthalic acid

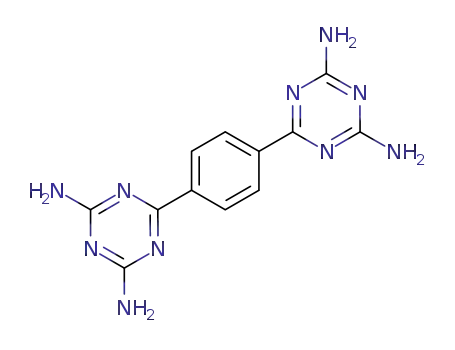

6,6′-(1,4-phenylene)bis(1,3,5-triazine-2,4-diamine)

di(2-ethylhexyl)terephthalate

CAS:112163-33-4

CAS:112-34-5

CAS:88980-06-7

CAS:147-94-4